Types Of Braking System In Trucks – Know The Different Brakes’ Functionality

The braking system is arguably the most critical component of the vehicle on a car or truck, along with the steering wheel, engine, and wheels, whenever it comes to avoiding an accident.

It is particularly common on trucks, tractors or trailers, which are noticeably heavier than standard vehicles, weighing more than twenty times as much as a typical passenger vehicle, even when unloaded. And also, This extra weight makes it more challenging for the trucker to slow down or stop the truck to prevent a collision. Ironically, these collisions are significantly more harmful to the cars involved than the truck that smashes them. It underlines the value of the truck brake system.

Becoming acquainted with the truck air brake system and how they function is essential for keeping everyone safe while travelling as a driver. What you must know about them is as follows.

Understanding Truck Braking System

Trucks and tractor-trailers comes with three unique braking configurations:

- the service brake,

- the parking brake,

- and the emergency brake

On the other hand, the parking brake and the emergency brake employ the same technology; the only variation is when they’re in the activating mode.

The truck braking system performs various functions. For starters, it maintains a constant flow of compressed air. It also needs to direct the movement of that air. Ultimately, it converts the energy of air pressure into mechanical pressure.

Know About The Truck Brakes Importance

A truck’s air brakes are a useful component that a driver or anyone can’t avoid at any cost. The main purpose of air brakes on trucks is to:

- To bring a moving truck to a halt.

- To slow down a speeding truck.

- For secure parking of a truck on a firm or sloping surface.

- As a safeguard against sudden calamities.

- To protect the truck from injuries caused by overwhelming road situations.

How Air Brakes Work on a Truck?

Let us now make you understand how truck air brakes work. It will help you gain in-depth knowledge about truck brakes and how to use them effectively.

Below is a basic description of how an air brake system on a commercial vehicle operates.

- Truck air brakes continue to function on compressed air rather than hydraulic fluid. Air brakes might be a drum, disc, or mixture.

- An engine-mounted compressor pressurizes the air. Then, the air compressor pumps the compressed air into air-holding tanks, where it is stored until required.

- Air pressure activates the service brakes and relieves the parking brake. The system contains several air circuits. Whenever the air pressure in the chambers is forced to release, the parking brake activates by spring force in the parking brake part of the spring brake chamber.

- It also enables the parking brake to function as an emergency braking device. If the air pressure becomes too low, the force generated by the springs in the chambers will be sufficient to compensate for the stresses imposed by the air on the diaphragm and pressurize the brakes to all four wheels.

- The semi-air brakes are comparable to hydraulic brake circuits in their operation. Whenever the operator pushes the brake pedal, air tension is transferred to the wheels in the same way as hydraulic pressure is released to the wheel in a hydraulic brake circuit.

Professional expertise and a proper understanding of truck brakes working can help you in operating air brakes securely. So, keep everything in mind and train yourself professionally before driving a truck or any vehicle.

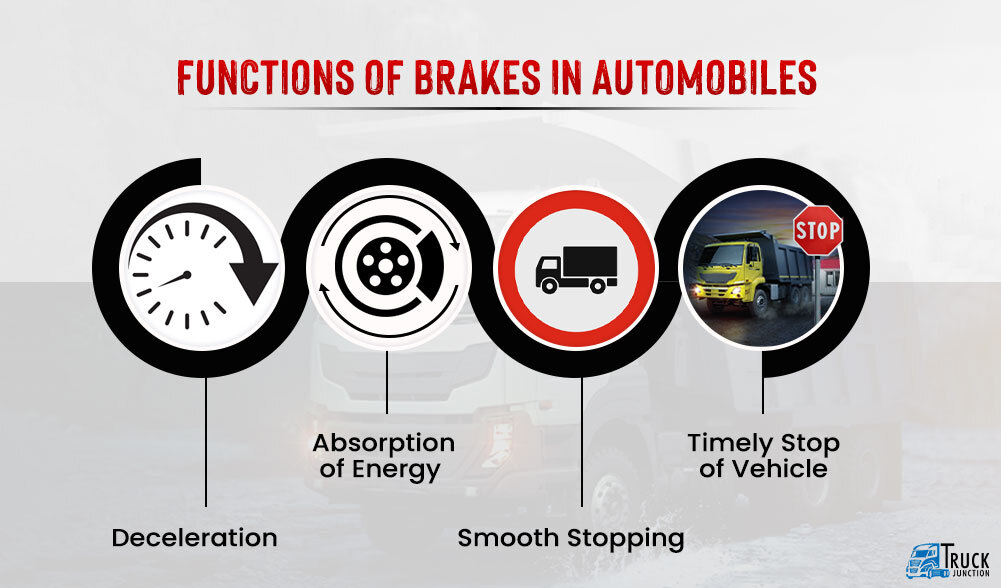

Functions of Brakes in Automobiles

A Braking System in a Truck is an important element. Regardless of what type of automobile individuals drive, an effective braking system remains a top priority for their safety.

Now, we will discuss the truck brakes’ functionality in detail for better understanding:

A. Deceleration

The primary purpose of the brake system is to slow or decelerate a truck. Tapping on the brake pedal compresses the brake pads against the rotor linked to the tire, resulting in the vehicle slowing down owing to friction.

B. Absorption of Energy

A brake system hydraulically or electronically accumulates the kinetic energy produced by the vehicle to slow down its speed. Friction turns kinetic energy into heat in mechanical brakes. An electric current drives a magnet to activate the brakes in electric brakes.

C. Smooth Stopping

The braking system adds resistance to counteract movement and slow or smoothly halt the vehicle at a specific distance.

D. Timely Stop of Vehicle

The braking system’s purpose is to stop the automobile in the shortest possible distance which accomplished by transferring the vehicle’s kinetic energy into thermal energy discharged into the environment.

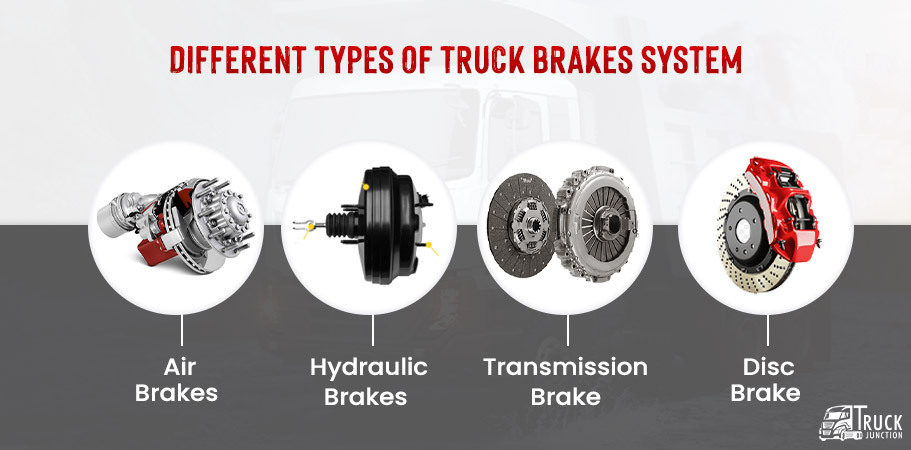

Different Types of Truck Brakes System

You are now familiar with the definition and main functions of the truck’s brake system. It is now time to know about the different types of truck brakes classified into four main categories. And these are:

1. Air Brakes

The first and foremost Types Of Braking System in the truck is Air Brakes. Air braking systems are often used in big vehicles such as buses and trucks. And also, The brake pedal is activated, like with other models. But instead, air from the surrounding flows into the compressor via an air filter and is routed to the reservoirs via an unloader valve. It then reaches the brake chamber via a brake valve that controls the amount of braking. It causes braking.

2. Hydraulic Brakes

This type of truck brake provides the most dependable and practical braking system. The hydraulic pressure applies the braking force.

The hydraulic brake truck process works only on Pascal’s law. It indicates the frequency of pressure produced by a liquid inside the isolated environment always be equally distributed in all directions.

3. Transmission Brake

A truck transmission brake is a type of brake that works on a vehicle’s transmission system instead of straight on the wheels. In simple words, the trans-brake, also known as the transmission brake, is a device that allows the operator to rotate the wheels and gear up the engine to maximum throttle. It will also enable the vehicle to remain motionless without straining the brakes and allowing it to hit top speed when needed. The trans-brake provides the optimal acceleration for your vehicle. It is an ideal for full RPM at the beginning of a race, and epitomizes what it signifies to be prepared to go.

4. Disc Brake

A truck disc brake comprises a cast iron disc connected to the wheel hub and a stationary housing called a calliper. The calliper attaches to a fixed portion of the automobile. Also, it divides into two pieces, either possessing a piston. A friction pad is located amongst each piston and the disc and is held together by holding pins, spring plates, and other mechanisms. The calliper has provisions for the fluid to access and exit each housing. And also, There are additional connections to some different pathways for bleeding. Every cylinder has a rubber sealing ring between the cylinder and the piston.

When you use the brakes, a conventional hydraulic piston moves the friction pads making contact with the disc and generating equal and opposite pressures to the latter. When the brakes release, the rubber sealing rings serve as returning springs, retracting the pistons and friction pads away from the disc. It is how heavy-duty truck disc brakes work.

Thoughts Before Closing

The essential safety aspect of any automobile is its brakes. Understanding the various types of brakes, either inside or between trucks can assist you in becoming more knowledgeable when looking for and maintaining your brakes.

Therefore, thoroughly understand the complexities of your Tata truck air brake system to make your travel smooth even on rough terrains.