Different Types Of Truck Engines – Know Its Working and Applications

Every moving thing in the world is operated by a certain type of mechanism which we call a machine. Also, we can witness this thing from our home to the outside world, many devices with significant functions and principles of operation. In automobiles, the mechanism which operates the vehicle is called an engine. The basic concept of a vehicle’s engine is to produce the required energy needed to complete all the tasks. Also, mainly in trucks or commercial vehicles, the engine is based on diesel fuels as it has many benefits regarding efficiency, power and other points.

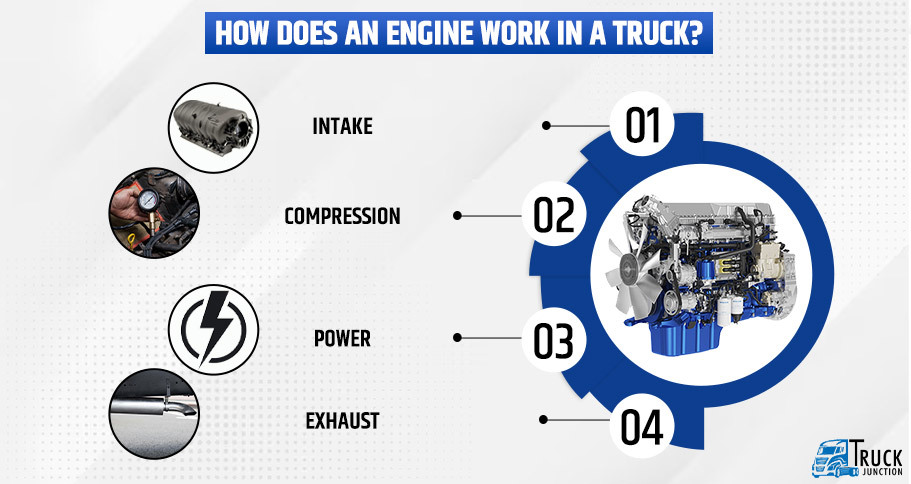

The truck engine is the heart of the whole system as this is the mechanism which delivers all the energy for applications. The working principle of all the engines is almost identical to each other. A diesel engine is a type of internal combustion engine which burns the fuel inside by injecting a mixture of hot, high-pressure compressed air and fuel. Also, In the old times, external combustion engines were used like the steam engine. Also, the working principle of any internal combustion truck engine consists of 4 steps: Intake, Compression, Power and Exhaust.

How Does an Engine Work in a Truck?

The diesel truck engine working principle is the same as the petrol engine, and it is divided into 4 parts which are written as follows:

- Intake

- Compression

- Power

- Exhaust

We will now understand all the steps happening while the truck engine works. So let’s start with the first point of it, which is intake. But before this, we need to know some of the basic terms of an engine which is important for understanding the working.

The power is generated by moving a piston inside the cylinder from up to down at a fixed distance. The top point of the cylinder is called the T.D.C. (Top Dead Centre) cylinder; similarly, the bottom end till it goes is called the BDC (Bottom dead Centre). The parts from where the compressed air mixture enters the cylinder and exhaust exit the cylinder are called Valves.

Intake Stroke the First Step:-

The process of intake or suction happens when the cylinder moves from T.D.C. to BDC while creating a vacuum inside the cylinder. This action opens up the intake valve from which the compressed air enters the cylinder. The whole process happens in milliseconds. This stroke is also known as the suction stroke.

Compression Stroke:-

In the second step of engine starting, the piston comes from the B.D.C. to the T.D.C. of the cylinder. The engine’s inlet valve closes, allowing the piston to rise and compress the air inside the cylinder. The Diesel engine does not use the air and fuel mixture; instead, it only uses compressed air, which helps prevent the engine’s pre-ignition problems. In addition, to improve efficiency, there are various things which we use. Currently, many companies are using turbocharged or supercharged engines. These things help throw more compressed air to increase efficiency of the truck engine.

Power or Expansion Stroke:-

In this step, the position of the piston stays at the Top Dead Centre, where the piston compresses air that is presented inside the cylinder. In addition, the fuel is sprayed in very small particles on the top of the piston where the compressed air is already present. This air is already at a temperature which can ignite the sprayed fuel. As a result, the fuel and compressed air mixture burn, and it causes an explosion inside the cylinder.

In addition, the other name for Diesel Engines is “Compression Ignition Engines” because the ignition happens with compressed air instead of an electric spark.

Exhaust or Final Stroke:-

We know that in the expansion stroke of the truck engine the force of fuel ignition impacts the piston to travel down at high speed, and it starts the engine functioning. As a result, now, because of inertia will push the piston upwards. Also, this action will open the exhaust valve, and all the waste of ignition or burned gaseous fuel mixture will exit from here.

Different Types of Engines In A Truck

Currently, companies in the automobile sector use four-stroke engines as they are highly efficient. However, the other type of automobile engine used was the two-stroke engine. In these engines, the working happens with the four strokes: Intake, Compression, Power and Exhaust. But in the two-stroke engines given, 4 steps happen in two, first intake and compression, and the other step consists of expansion and power stroke.

Difference Between Two-Stroke and Four-Stroke Truck Engines:-

As we have discussed, the basic difference between the 2-stroke and 4-stroke engines is the distribution of stroke. But there are some other factors present which make the engines different from each other. In addition, some of the points are present in the following table.

| S. No. |

Two – Stroke Engines |

Four – Stroke Engines |

| 1 | The weight of the two stroke engine is lighter. |

The weight of the four stroke engine is comparatively heavier. |

| 2 |

The wear and tear of the engine is high in these types of engines. |

The wear and tear of the engine is low in the four stroke engines. |

| 3 |

The maintenance cost of the two stroke engines is less. |

Four stroke engines come with low maintenance high. |

| 4 |

The two stroke engine has low efficiency and produces high smoke at the time of exhaust. |

The four stroke engines are more efficient and also generate very low smoke which means the fuel is fully burnt. |

| 5 |

The lubrication consumption of the two stroke engines are very high. |

The lubrication consumption of this engine type is less which makes the running cost low. |

| 6 |

The two stroke engine generates less power and high torque. |

The power output of this engine is high and the torque generation is low. |

Different types of Engine Technology in Trucks:-

Many truck technologies are getting added to the truck engine to enhance performance.

CRDI:- Common Rail Direct Injection

TGDI:- Turbocharged Gasoline Direct Injection

TDi :- Turbocharged Direct Injection

MPFI:- Multi point fuel injection

S.C.R.:- Selective Catalytic Reduction

D.E.F.:- Diesel Exhaust Fluid

EGR:- Exhaust Gas Recirculation

Thoughts Before Closing

The current age is witnessing many inventions which will change the future of the commercial vehicle industry. In addition, these inventions are a result of constant improvement in the previous technologies and result in a bright and greener future. Also, in truck Engines, diesel is the most famously used fuel; hence, it is still in use, and it is important to know the overall working of this machinery.

Related Blogs

Types Of Braking System In Trucks