Bi-Fuel Commercial Vehicles, The New Option For Diesel Engines

The Advancement in the commercial vehicles is not a new thing and we have often seen the effects it has created on the whole sector. The Bi-Fuel vehicles are doing the same and it has been one of the most praised inventions in this field.

What is Bi-Fuel? How Does that work? Is Bi-Fuel & Dual Fuel the same?

Well we are here to answer all the questions related to it, and also some more information. Let’s start this.

What is Bi-Fuel?

If we go by the name then Bi stands for two. So it’s simple that these types of commercial vehicles have two types of fuel. The bi-fuel commercial vehicles have 2 types of fuel and both of these fuels never mix with each other. As a result the two fuels in the bi-fuel engine are categorised as main fuel and one secondary fuel, the storage of the main fuel is bigger than the secondary. As an example, The Maruti Suzuki Super Carry is a Bi-Fuel MiniTruck and it has a storage capacity of 70 litres for the CNG fuel and 5 litres storage capacity for the petrol which works as a secondary fuel.

The CNG fuel creates a low carbon emission while burning, and the mileage of this vehicle is way better than the conventional diesel and petrol fuel.

What is the Need of Secondary Fuel?

Currently in India the infrastructure for the CNG fuel station and Electric charge station is not readily available at every given station. And, it will take time to completely create it. So We need a secondary fuel so if in any case of emergency the vehicle has enough fuel to take the vehicle to the nearest gas station. The new BS6 vehicles are even smarter in burning the fuel to zero carbon emission.

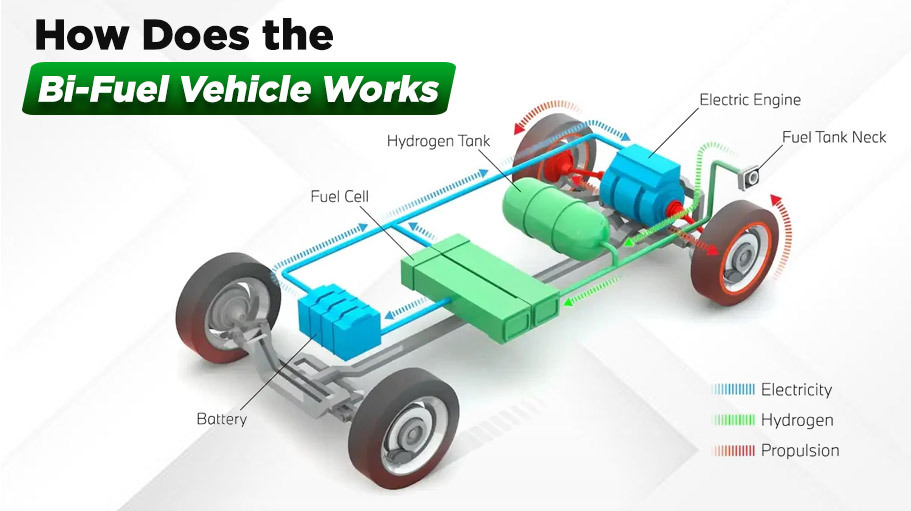

How Does the Bi-Fuel Vehicle Works

The Bi-fuel engine is a unique design which can work on two types of engine. The specifications and design of the engine is the same for both the fuels but the output is a little different. The working of Bi-fuel vehicles are very simple, both of the fuels are presented in different storage units in the vehicle. As we know the vehicle will have primary and secondary fuels in which primary has more storage and secondary has less storage. The vehicles will come with a change button by which you can change the fuel type. So as an example, if you are using CNG fuel and you want to change it, you can do it with a single button tap.

Benefits of The Bi-fuel Commercial Vehicles:-

The Bi-Fuel vehicles are designed and developed to increase the productivity of the vehicles and these vehicles clearly show the benefits. As we all know these vehicles are environmentally friendly and come with many benefits which improves the quality of work. Some of the benefits are here.

- Efficiency

- Sustainability

- Cost saving

- Longer Runtime

- Less Pollution Emission

Bi-Fuel Vehicles in Indian Market:-

The Indian Commercial Vehicle industry is also growing with global aspiration and we are watching new technologies being discovered here. Currently in India most of the brands are working on developing the technology of Bi-Fuel. Maruti Suzuki Super Carry and Tata Intra V20 Bi-fuel are the only commercial vehicles in the Indian market. In addition, both of these vehicles are compiled with Bi-Fuel engine in which they use CNG+Petrol engine.

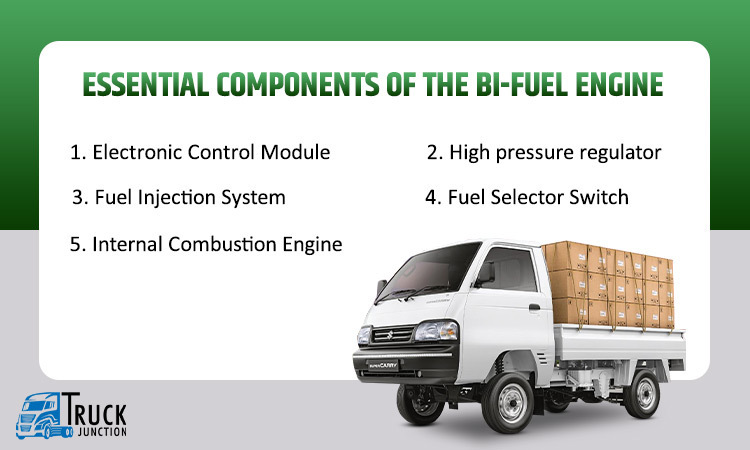

Essential Components of the Bi-Fuel Engine:-

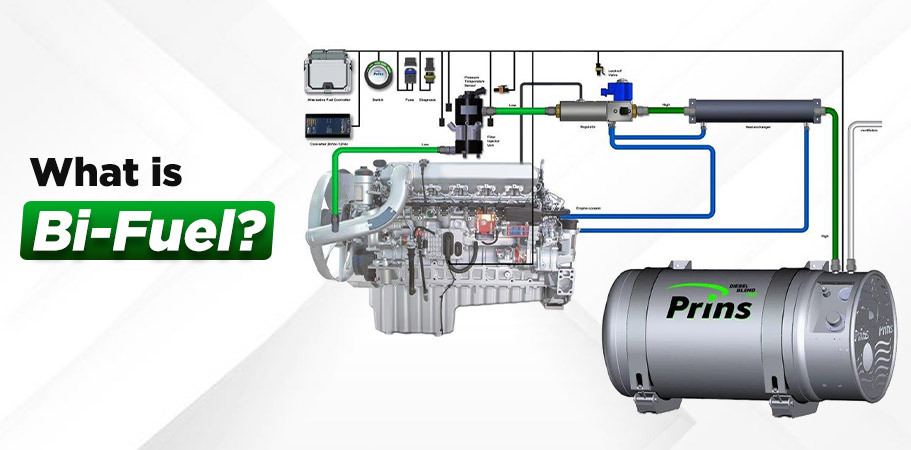

The engine of the Bi-fuel vehicle is the most important and it is designed and structured with many other components. Some of the things are the same like the conventional engine and some are changed according to the requirement. It will have a Battery, Electronic control module units, Fuel Fillers, Fuel Line, Fuel Tanks, Fuel Pump, Exhaust and others. Here we are going to talk about some of the parts of Bi-fuel engine mechanism.

1. Electronic Control Module:-

This engine is built with 2 ECM units, one for the primary fuel and one for the secondary fuel. Also, this unit controls the mixture, ignition timings, emission system, and it also safeguards the engine, detects the problems and solves them. In the Bi-fuel vehicles both the Electronic Control Model communicates and controls the mixture, ignition timings and emission and monitors the vehicle performance.

2. High pressure regulator:-

The high pressure regulator of the engine controls and regulates the pressure of the natural gas. The fuel in the storage tanks stays at high pressure, the regulator decreases. It works in lowering the pressure till it gets under the allowable or acceptable pressure. And then it sends it to the Engine’s Fuel Injection system.

3. Fuel Injection System:-

The Fuel Injection system in the Bi-Fuel engines are different for both of the fuels. Both of these FI systems take the fuel which comes from the High Pressure Regulator, and send it to the combustion chamber of the engine to start the process of combustion.

4. Fuel Selector Switch:-

As we know that the Bi-Fuel vehicles are designed to work on two types of fuels and hence it comes with the fuel selector switch. The fuel selector switch allows the driver to change the type of fuel for the engine on requirements.

5. Internal Combustion Engine:-

The Internal Combustion Engine is the place where the fuel-air mixture comes and ignition happens. The engine is a spark ignition engine and comes with a spark plug. The fuel entered the chamber either by the Fuel Injection or the intake manifolds.

Conclusion:-

CNG or other Natural Gas based trucks can become a permanent resolution of high pollution but considering todays’ scenario, Bi-fuel trucks are the way to go. The infrastructure of CNG gas stations is still not up to date in all the places and we need a secondary fuel with it. The engine structure for both the fuels are almost identical, just one of two components in the engine are different. Total Operation Cost of the engine is less in comparison, in addition the fuel efficiency of the engine is good.

Related Blogs

Top 10 CNG Truck Models in India