Different Types Of Truck Chassis – Know Its Functions & Applications

The term chassis derives from a french word signifying the main structure of a vehicle. In literal meaning, Chassis is the load-bearing framework that supports its components and functions structurally. Many people don’t know more about the chassis of a truck. Do You Know? If you are one who does not know much but has a keen interest in getting further details regarding truck chassis, this post is for you. Moreover, the rolling chassis truck refers to the truck frames with running gears, including the engine, transmission, and suspension system. The truck frame considers being an essential part of the chassis on which the whole truck body and its components are mounted.

The chassis on truck is an external body structure that houses all truck’s components on the wheels with the help of a frame. Also, commercial truck chassis is a complete truck without a body. This is similar to a complete human without a dress. Today the manufacturing process called Body-on-frame construction is used to bolt heavy-duty trucks with chassis flexibly. Commercial vehicle manufacturers come with Chassis only, Cowl & Chassis, and Chassis Cab variants that outfit with particular bodies.

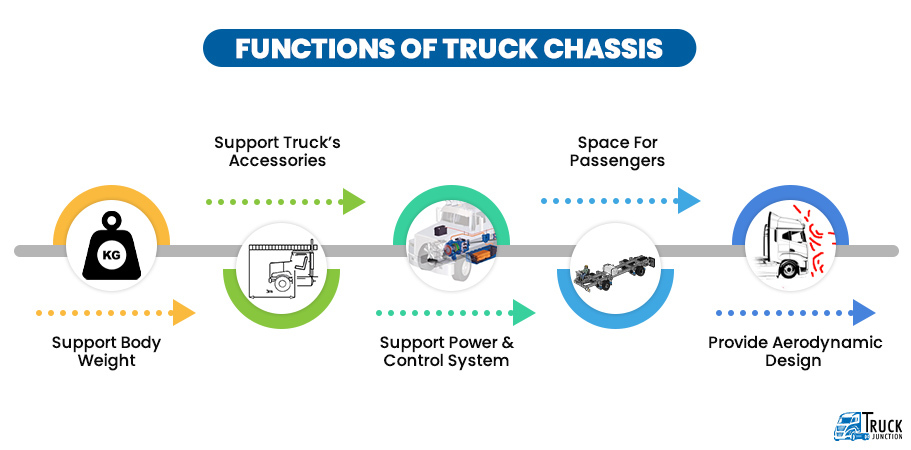

Functions of Truck Chassis

Chassis constructs with long sections called longitudinal members located on either side. The longitudinal members and side members fit together with the help of rivets and bolts. Further, there are generally 5-6 cross members that provide stability and strength to the chassis. For facilitating torsional rigidity, diagonal cross bracing is present in the chassis. Below are some of the key essential roles and functions of the truck chassis.

1. Support Body Weight

The manufacturing of chassis technology for a truck relies primarily on the load-bearing capacity of the truck chassis. This capacity supports the body weight of the truck. Brackets provided in the chassis frames help to mount different weights of components like the engine, suspension leaf springs, brake shafts, and others.

2. Support Truck’s Accessories

An extended part of the truck frame over the front axle is the front overhang, while beyond the rear axle is the rear overhang. Trucks’ accessories like clutch, transmission and engine aggregates rivet together into an assembly. Additionally, the front overhang of the truck chassis mounts these components by using rubber blocks.

3. Support Power & Control System

All the members used in constructing the chassis frame build with pressed steel. Pressed steel helps to protect the power and control system of the truck from engine vibrations. The members, like rubber blocks, not only support a truck’s power system (engine) but also isolate the engine from road shocks. Heavy truck chassis is different from a car’s chassis due to the higher loads carried by its power system with continued operations.

4. Space For Passengers

The truck chassis working is to maintain the shape of the truck, which further ensures the appropriate space for passengers. Longitudinal members of the chassis frame move upswept in the front & rear, giving proper space for the axle’s movement. In addition, this lowers the frame height with a smaller turning circle to give a better steering lock.

5. Provide Aerodynamic Design

With the perfect aerodynamic design, the drag truck chassis reduces the air-dragging force. It helps in enhancing the truck’s performance and productivity. The custom truck frames maintain stability and help in providing a contemporary design. Furthermore, the aerodynamic design depends on the types of chassis frames.

Truck Chassis Types Based On Different Factors

In the automobile sector, different types of truck chassis are available for different suitability. Mainly commercial vehicles categorise into two type of truck chassis, namely Conventional and Non-Conventional Chassis. A truck with conventional chassis has a frame support to bear loads of engine, brake, suspension, transmission, and others. Moreover, this is Body-on-chassis equipped in heavy-duty trucks, SUVs, etc. However, non conventional chassis are frameless chassis that work as unibody chassis. This is suitable for advanced cargo trucks with modern technology.

Conventional Chassis Versus Non Conventional Chassis

| Convention Chassis | Non Conventional Chassis |

| It has a frame to support the body. | This is frameless chassis. |

| It is also called Body-on-chassis. | This is also called unibody chassis. |

| More vibration and shaking of loose parts due to frame joints. | Lesser or no vibration due to the absence of frame joints. |

| It does not consume lesser fuel relatively. | This consumes lesser fuel comparatively. |

| Lower body rigidity & weight doesn’t make better handling. | Higher body rigidity & weight makes handling better. |

| Higher load capacity and strength. | Lower load capacity and strength. |

| Tough to resist any damage during a collision. | Not tough to save in case of any collision. |

| Easy to repair after a collision. | Not easy to repair after a collision. |

| It fits in bigger vehicles like heavy-duty trucks. | This fits in modern vehicles like luxury trucks. |

The truck chassis types depend on factors like engine location, assembly, frame, and others.

A. Based On The Engine Location

Below are the chassis types based on engine location.

- Conventional Chassis: The engine fits in front of the driver’s cabin in the truck with conventional chassis. Also, it ensures the driver’s seat is far from the front axle. This type of truck chassis has better strength and higher loading capacity. In this, fitted components can easily be repaired and dismantled. With an additional heavyweight, it consumes much fuel.

- Semi-Forward Chassis: The engine is located half in the driver’s cabin and half in the front of the driver’s cabin. Also, the space provided by half-engine fitment inside the driver’s cabin is utilised completely. Tata 407 Gold SFC 29 WB is the best example of this light truck chassis. You can get a spare parts page with Tata truck chassis prices at Truck Junction.

- Full Forward Chassis: In this, the entire engine fits inside the driver’s cabin. Hence, the driver of the truck with full forward chassis sits above the front wheels. With this engine fitment, the driver is able to see the road surface completely in front of the tyres.

- Centre Engine Chassis: This is also called a Mid-engine chassis. As the name implies, the engine mounts between the front wheels and rear wheels. Its arrangement improves the wheel grip and provides greater aerodynamic efficiency.

- Rear Engine Chassis: The centre of gravity of the engine is behind the rear wheels due to the engine’s location at the rear side. Further, the transit mixers and low-floor buses equip with this truck chassis. Hence more space is available for passengers and luggage.

B. Based On The Assembly

Below are the chassis types based on assembly.

- Integral Chassis: With frameless chassis, the body shell and under-body parts are welded together into a single unit, helping to decrease the overall weight. Since it does not produce a long chassis truck, this truck chassis price is lower. Its demerit is the difficulty in repairing.

- Semi Integral Chassis: The engine instals on a frame in the truck attached to this truck chassis type. Because the engine fits on the frame, the other remaining portion of the chassis is frameless. That’s why in case of collision, the only front part of the truck repaired.

- Conventional Chassis: In this truck, the side members or longitudinal members are riveted together by 4-5 cross members. Moreover, all body components house in this structure.

C. Based On Truck Frame Types

Below are the chassis types based on the different types of frames of the truck.

- Ladder Frame: It follows the two-dimensional shape of a ladder. This truck chassis has two side or longitudinal members welded by 4 or 5 cross or lateral members.

- Backbone Frame: This incorporates a strong tubular backbone chassis frame which bears most of the body weight.

- Tubular Space Frame: It follows a 3D pyramid-style structure and diagonally braced tube boxes. The space frames are all about tubes joint together in compression and tension.

- Monocoque Frame: Monocoque word is a combination of two words, Mono and Coque. Mono is a Greek word that means single, while Coque is a French word that means shell. This truck chassis is a construction technique that supports the structural loads using objects’ external skin.

- Aluminum Space Frame: Since the monocoque steel chassis is heavier, so it got its alternative in the form of Aluminum material. This truck chassis is similar to the monocoque design, and the only difference is Aluminum in place of steel. Further, small commercial vehicles like mini trucks and electric truck chassis follow this frame.

- ULASAB Frame: The Ultra Light Steel Body Monocoque Frame is a new type of steel monocoque technology developed by American manufacturers. This chassis emerged to get the lighter alternative of the Aluminium space frame.

- Carbon Fibre Frame: This is a monocoque-type chassis frame made of carbon fibres. Additionally, this truck chassis follows a great rigidity-to-weight ratio.

In A Nutshell

We believe this post is useful for knowing more about chassis and its functions. The chassis is different from the frame, which is only an essential part of the chassis. As we have discussed different truck chassis, you can understand automobile chassis properly. Furthermore, the shape, seating capacity, and cargo deck length of a truck depend on truck chassis lengthening. You can get information and buy truck chassis at Truck Junction. Also, the cargo load body of a truck varies with chassis sizes like 4×2 chassis, 6×4 chassis, 8×4 chassis, 6×6 truck frame, and others. As per your truck’s requirements and application for your business, you can choose your custom truck chassis.